Drafting, construction and manufacture of tools and products

FOR

ENGINEERING

We have a wide range of CNC and electrical discharge machines, including 5-axis mills, multifunction lathe centers, sinker EDM, wire EDM, and 3D scanner. Our machine equipment allows us to specialize in products for all fields of engineering that are complex in shape and geometry.

-

MORI SEIKI NMV 8000 DCG/40 D

Travels(X/Y/Z) 1 200/920/610 mm

Workpiece size: max o 1000 mm

Table clamping surface: o 800 mm

Table maximum load: 1 000 kg

Spindle speed: max 12.000 rpm

Control system: FANUC

DECKEL MAHO DMU 60 MONO BLOCK

Travels(X/Y/Z) 730/560/560 mm

Table clamping surface: 1 000 x 600 mm

Table maximum load: 500 kg

Spindle speed: max 12.000 rpm

Control system: Heidenhain iTNC 530

Internal cooling through spindle

A probe for measuring the workpiece,

and laser measurement of the tool length and diameter.

CNC HORIZONTAL MILLING MACHINE WITH SMOOTH 3D ROTARY TABLE - 4TH AXIS 2X MORI SEIKI NH 5000 DCG

Travels(X/Y/Z) 730/730/850 mm

Pallet clamping surface: 500x500 mm

Spindle speed: 14000/20000 rpm

Table maximum load: 500 kg

Control system: FANUC

Smooth rotary table - 4th axis

A probe for measuring the workpiece, and laser measurement of the tool length and diameter

-

MORI SEIKI NVD 7000/40

Travels X/Y/Z 1540x760x660

Table clamping surface: 1700x760 mm

Spindle speed: 14.000 rpm

Table maximum load: 2 000kg

Control system: FANUC

A probe for measuring the workpiece, and laser measurement of the tool length and diameter.

MORI SEIKI NVD 6000 DCG

Travels X/Y/Z 900x600x450

Table clamping surface: 1000x600 mm

Spindle speed: 20.000 rpm

Table maximum load: 800kg

Control system: MORI Seiki

A probe for measuring the workpiece, and laser measurement of the tool length and diameter.

MORI SEIKI NVD 4000

Travels X/Y/Z 600x400x400

Table clamping surface: 750x450 mm

Spindle speed: 30.000 rpm

Table maximum load: 350kg

Control system: MORI Seiki

A probe for measuring the workpiece, and laser measurement of the tool length and diameter.

DECKEL MAHO DNNU 80T

Travels X/Y/Z 600x400x400

Table clamping surface: 750x450 mm

Spindle speed: 30.000 rpm

Table maximum load: 350kg

Control system: MORI Seiki

A probe for measuring the workpiece, and laser measurement of the tool length and diameter.

-

-

MORI SEIKU NT 4300 DCG/1500S – MULTIFUNCTION MACHINING CENTER

Max. turning length: 1498 mm

Max. workpiece weight:

when clamped in one spindle: 450 kg

when clamped in both spindles: 900 kg

Control system: FANUC

A probe for measuring the workpiece and tool.

SE 820 NUMERIC

Max. swing diameter over bed: 800 mm

Max. swing diameter over support: 515 mm

Max. turning length: 2000 mm

Spindle drilling: 133 mm

Max. speed: 1600 rpm

-

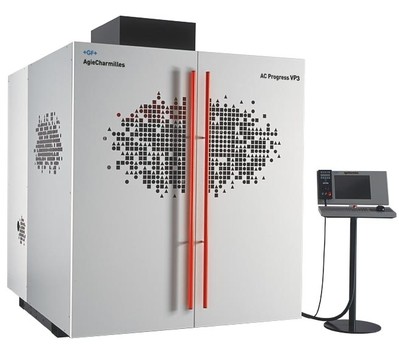

AGIE PROGRESS VP3

Travels (X/Y/Z): 500/350/426 mm

Max. workpiece weight: 600 kg

Cutting angle: +/- 30 ° / 100 mm

PEPS programming software for 4-axis cutting

AGIECUT CLASSIC 2S

Travels (X/Y/Z): 350/250/256 mm

Max. workpiece dimensions: 750x550x250mm

Max. workpiece weight: 450 kg

Cutting angle: +/- 30 ° / 100 mm

PEPS programming software for 4-axis cutting

-

-

EDM sinker (spark) and driller

AGIECHARMILLES FORM 200 SP

Travels (X/Y/Z) 780/530/350 mm

Max. workpiece dimensions: 350x250x300 mm

Max. workpiece weight: 500 kg

Max. electrode weight: 50 kg

AGIEDRILL

CNC high-speed EDM driller machine with revolving head for starting hole drilling - 0,5 / 1 mm

-

DIMENSIONAL INSPECTION DEPARTMENT

3D MEASURING MACHINE LK INTEGRA 10.7.6 - MANUFACTURING COMPANY METRIS

Travels (X/Y/Z): 1016/711/610 mm

Max. workpiece dimensions: 750x550x250 mm

Measuring accuracy: + 1.75 L / 350 µ

Max. workpiece weight: 822 kg

ATOS CORE 300 3D SCANNER

Measuring area: 300x230 mm

Working distance: 440 mm

-

-

FOTRUS 250MC 3D PRINTER

Working area: 254x254x305 mm

Material: ABSplus-P430

-

FNK 25 – FA 3U – FA 3H – FA 3AU – SV 18 R – SU 32 - SU 50A – BUA 16A – BUA 25

![]()

Turning - max. turning diameter: 450 mm, accuracy: +/- 0.02 mm

Surface grinding - max. 300x1000 mm, accuracy: +/- 0.01 mm

Cylindrical grinding - max. length: 600 mm, accuracy: +/- 0.01 mm

Milling – max. 600x400x200, accuracy: +/- 0.05 mm

Coordinate drilling – max. 800x1200 mm, accuracy: +/- 0.005 mm

-

-

Thanks to modern technologies, our machine equipment enables us to productively machine a wide range of components and materials.

We are a stable engineering company with main focus in cutting operation and EDM machining of metals, and assembly sets. We concentrate on providing the latest technologies that ensure ideal outcomes of our production.

Thanks to a wide range of high-quality machines, we offer CNC machining, conventional machining, and also machining with 5-axis multifunction machining centers.

The aim of our company is to produce a highly accurate products and components that will satisfy even the most demanding clients of all fields of engineering. The combination of modern equipment and quialified and experienced staff enables us to offer top quality services.

We guarantee high quality by modern output control and 3D measurement with high accuracy.

We are a holder of the ISO 9001 certificate, which obliges us to adhere to standards and norms in effect and customer demands.

Feel free to contact us at: alform@alform.cz